by Bruce Pease

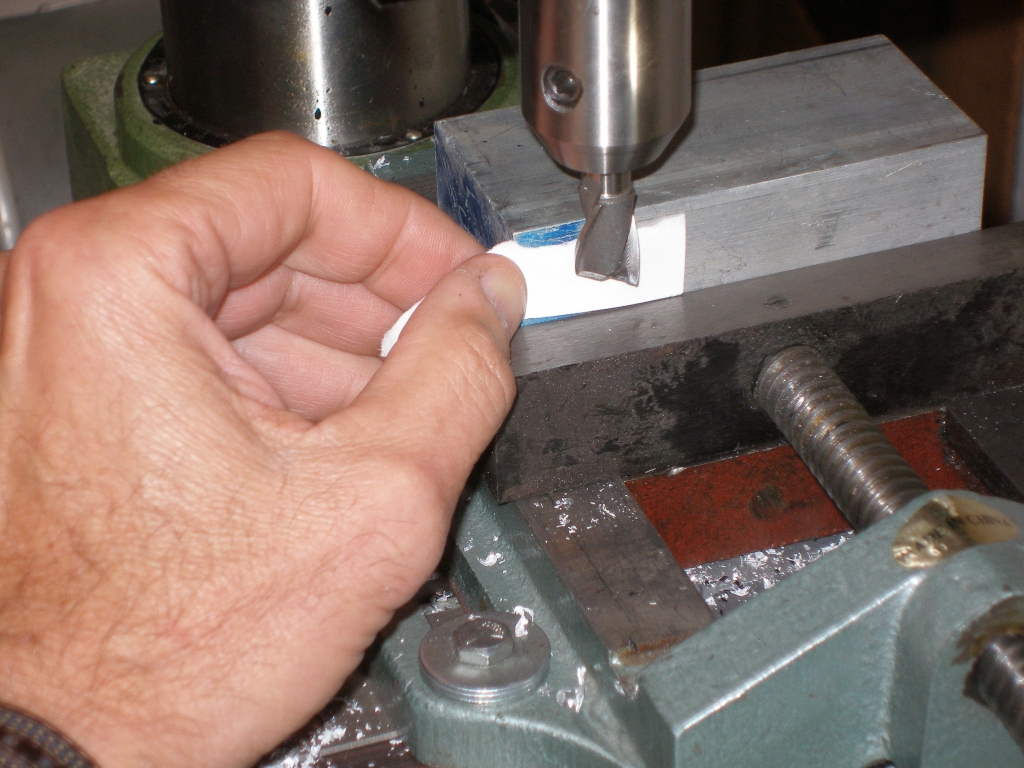

Many times a milling cut needs to be dimensionally close, but not super accurate. To start the milling process, the material’s edge needs to be located. A quick way to find the material’s edge was taught to me by my Dad. Simply tear off a small piece of paper and position it between the rotating cutter and the material. Holding the paper loosely, move the cutter toward the paper, slowing down as the clearance closes. At some point the cutter will snatch the paper away and you have found the edge. Repeat this for the other table axis and you now have the X- and Y-datums from which the milling can begin. Typical paper is about .004″ thick, so an easy adjustment of .004″ improves the accuracy even more.

(click to enlarge)

Thanks Bruce! Your Subscription has been extended an issue!

Digital Machinist now has a page on Facebook!

And check out our Twitter feed!

Please do us a tremendous favor and forward this e-mail on to your machining friends!

Are you not a subscriber to DIGITAL MACHINIST? Visit us at www.digitalmachinist.net and request a no-obligation issue, or call and request it at 1-800-447-7367. Tell them you received an e-mail from a friend!

And don’t forget to check out Digital Machinist’s page on Facebook and our Twitter feed!

Your friend thinks you’ll enjoy DM, or you wouldn’t have this e-mail!

We hope you enjoyed this e-mail tip, brought to you by your friends at Digital Machinist.

Get Involved!

Do you enjoy our e-mail tips? Has one of them ever “knocked something loose” in your head? Your tip could be a future e-mail blast from your favorite magazine. Just send your tips to george.bulliss@VPDemandCreation.com. If we use your tip, we will extend your subscription by an issue. We like to see 200 to 300 words, plus an image, if available. Thanks!

We hope you enjoyed this e-mail tip, brought to you by your friends at Digital Machinist, dedicated to precision metalworking.